15 August 2012

The Institute for Industrial Productivity (IIP) has released its interactive and user-friendly database of industrial energy efficiency technologies and measures to help companies boost their competitiveness and create environmental benefits. IIP’s Industrial Efficiency Technology Database (IETD) delivers rich and relevant information about the latest and best available technologies, tools and management systems to facilitate the accelerated and full commercial deployment of energy efficient and low-carbon technologies and practices in industry.

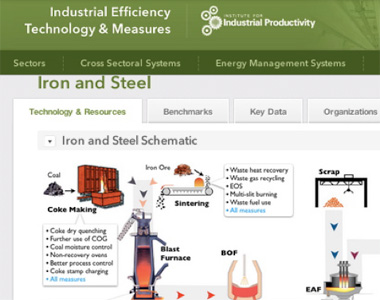

The database contains more than 300 technology options, as well as performance and cost benchmarks, case studies, and key data and initiatives for specific sectors and crosscutting systems. Currently, the database contains information for the cement, and iron and steel sectors, as well as electric motor-driven systems. Pulp and paper, and glass industries will be added shortly.

The interactive diagrams and advanced search functions help companies, industry associations, program implementers and others easily and quickly locate relevant technologies and measures. Users can navigate technologies by industrial processes or directly go to some of the selected technologies/measures applicable to that sector or system.

Technologies and measures are presented along with information on their energy and CO2 saving potentials and implementation and operation costs to assist companies in assessing the cost-effectiveness of investment options for greater profits.

The IETD is among IIP’s package of databases that aim to support industry and government decision makers find out about the best practices in technology, policy, and financing to improve industrial productivity. Our databases are publicly available and offered free of charge, as part of our mandate to increase industrial energy productivity in energy intensive sectors. IIP endeavors to continuously improve the quality, and increase the scope, of information in this database, and welcomes feedback and input from users to this end.

The Institue for Industrial Productivity acknowledges Fraunhofer ISI, IREES, LBNL-China Energy Group, E3M Inc., ISR-UC and Holtec for their valuable contributions. To get more information or provide feedback, please contact Murat Mirata (murat.mirata@iipnetwork.org).